- #Cutlist plus fx woodworking software update#

- #Cutlist plus fx woodworking software pro#

- #Cutlist plus fx woodworking software software#

- #Cutlist plus fx woodworking software free#

In this case you might want to make identical but unique Components for the distinct legs so that you can give them distinct names that CutList will sort separately. So, if you need to hand off the list to someone who will not only rough cut the parts but also do followup joinery, etc., it may matter to you that CutList put them on the same line. This makes a big difference when you are doing the joinery (don’t ask me how I know that) but is irrelevant to CutList because both legs are still the same size and come from the same component. However, if the legs are tapered, the orientation of the mortises in one front leg with respect to the taper is different for one side vs the other.

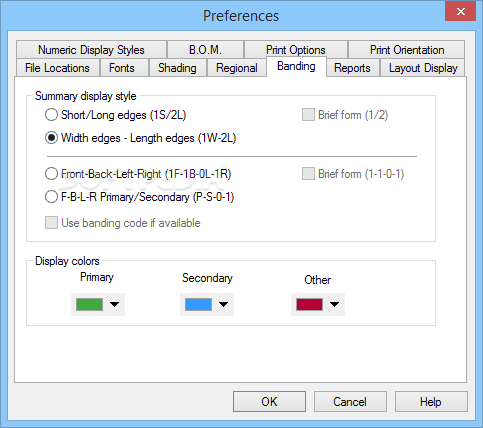

They can usually be created by mirroring a single Component in appropriate directions, so CutList considers them to still be the same and puts them on a single line. A typical example is the legs of a table. However, if you scale instances (for example to create 6’ and 8’ 2x4’s from a single component) they will list on separate lines in the table because they no longer have the same exterior dimensions.Ī “gotcha” here is that mirroring a part (one kind of scaling) does not cause the two instances to get separate lines because that operation does not change the exterior dimensions. That is, all parts that are unscaled instances of the same definition will get the same name and will be aggregated on the same line of the output (unless you select tables sorted by subassembly, in which case the parts within the same subassembly will go together on one line but different subassemblies will get separate lines). It does not consider details such as joinery unless they affect the bounding box.ĬutList distinguishes between parts based on two things: the name of the ComponentDefinition and the dimensions of the specific instance’s bounding box. It is focused on the exterior dimensions (bounding box) because that is what you will need to saw out. If you have questions or comments email me.This leads to some important observations about best modeling in SketchUp for usage of CutList that make your question not quite as dumb as it might at first sound.Īs its name suggests, CutList is geared toward planning the rough cutout of parts from stock. So if you use it please let us know how it works for you. In the live version the menu item label is CutList Plus – beta.

#Cutlist plus fx woodworking software update#

This week’s update will include this function.

You will need Version 4 of SketchList 3D to use the direct data passing function.

#Cutlist plus fx woodworking software free#

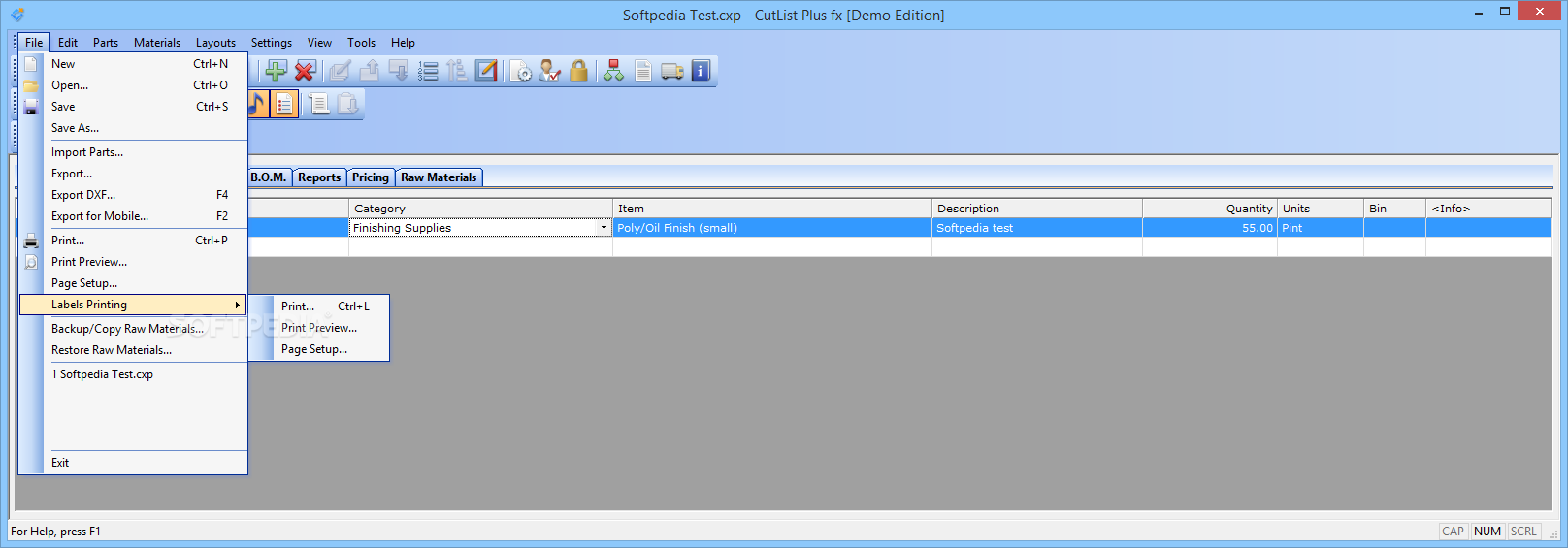

(This is a free update for current Gold/Platinum fx customers.) Check out their webpage for prices. Support for this “Direct Integration” with SketchList 3D will be available in the Gold and Platinum Editions of CutList Plus fx 12.3 and later. It will create a file and pass the data onto CutList Plus where it will be used for your layouts. For the time being it is labeled ‘beta’ since we may make some adjustments after we get some user response. On SketchList 3D the export function is under the report menu item. We agreed that it is a good idea so we did it. I contacted Todd Peterson of Bridgewood Design and suggested an interface from SketchList 3D to CutList Plus. For some reason I only remember sheet goods – but my memory isn’t what it once was. Then I would get the material layout diagrams. I’d pull off a parts list and key it into the form of CutList Plus.

#Cutlist plus fx woodworking software software#

In fact CutList Plus was the first woodworking software package I ever bought – maybe 15 years ago. One guy liked the iPad reporting feature of CutList Plus and wanted to use his iPad in the shop.

#Cutlist plus fx woodworking software pro#

Now being that SketchList 3D Shop and Pro versions already have an integrated optimizer I called these users to find out why they wouldn’t just use the one they just bought as part of SketchList 3D.Ī large part of the answer was they were used to CutList Plus and wanted to continue using that. It also calculates how much material to buy for your project, and what it will cost. It generates optimized sheet layouts that allows you to make the most efficient use of your plywood panels and lumber. Several months ago some new SketchList 3D users wrote in asking how they might export parts data for input to their CutList Plus program.ĬutList Plus is offered by Bridgewood Design ( ). Announcing a CutList Plus direct interface from SketchList 3D Cabinet Design Software.

0 kommentar(er)

0 kommentar(er)